The "Incremental" Willys - Part II - The Build Continues - also known as the winter of 2002/3 refit.

Update - February 20th, 2003

2002 was a great year, both the Willys and I survived. Admittedly I required more surgery than the Willys but we are both ready for action in 2003. I missed quite a few outings because of health, the cold and rain this last Autumn. In 2002 some of the outings could have been a lot more pleasant if I had doors and a roof.

I purchased a generic soft top from Bestop. It is quite a good quality top. My biggest gripe would be the lack of visibility compared to running without a top. A ugly windshield riser was required to increase the roof height when using the MB windshield. It also has some pretty funky door channels that need to be attached to the windshield sides. I will probably remove these items and the top completely for the entire Spring, Summer and most of the Fall.

The roof bows fit over the roll cage with an inch to spare. This was my biggest concern. However, I did not allow for the bows to be folded to the back of the vehicle. This required major roll cage redesign. With the combined efforts of Larry and Brad Schultz it all came together. The doors make entry and egress quite an art form. When Tanker Schultz re-welded the cage he added some much needed grab handles. Without them I don't think I could ever get in the damn thing or get out without ripping off the doors.

(I'll post cage pictures later when it warms up enough for me to take the top off and repaint the roll cage.)

My first outing was January 1st at the Badlands. It was cold but dry. I was not used to having the extra height of the roof and I hit three different trees in off-camber sections. The trees finally won by slashing the roof. I now have a 6 inch ventilation hole. It's amazing - three years with the TJ and not a scratch in the roof. Three hours in the Willys and a six inch gash. Bloody marvelous!!!

To combat the cold I purchased a Heater Craft Heater from 4Wheel Drive Hardware. The heater includes: mounting brackets and hardware, 3-way switch, wiring harness, heater hose fittings, 12 feet of 3" vent hose, directional louvers with shut off vanes and instructions. Installation required cutting and custom routing of the heater hoses to the actual heater unit. The unit is a 12V DC three-speed centrifugal blower, 3.9/5.0/7.7 amperage draw, 172/228/263 CFM, up to 28,000 btu/h and weighs 7.2 lbs. Dimensions are 9.4" w x 6.4" h x 9.35" d. The unit fits very nicely under the dash considering how little room there is in the Willys. A mere 28,000 BTUs to heat the interior of a little Flatfender. No controls to adjust the amount of heat, just a 4 speed fan that fries you, grills you, broils you, or roasts you. That took care of the cold. While the "Wiz" Blocker was wiring the heater and switches he kindly installed and wired a power outlet for my GPS or hot weather fan.

The local law enforcement society decreed that a speedometer would be a useful addition to the Willys if I am to avoid tickets and future inspections by the local boys in Blue or black or brown depending on the town. John Toumbs Repair installed a matching Autometer speedometer that the fit the old hole perfectly. Amazingly enough the darn thing is accurate. He added a small tachometer to the steering column. While he was in the mood he also installed Autometer transmission temperature and engine oil temperature gauges.

The deep water and mud of Pittsfield took it's toll on the starter motor. I had this replaced by a local auto repair shop, while John replaced the gone-to-god alternator. Mean Green was tempting but I could buy 5 replacement GM units for the same money.

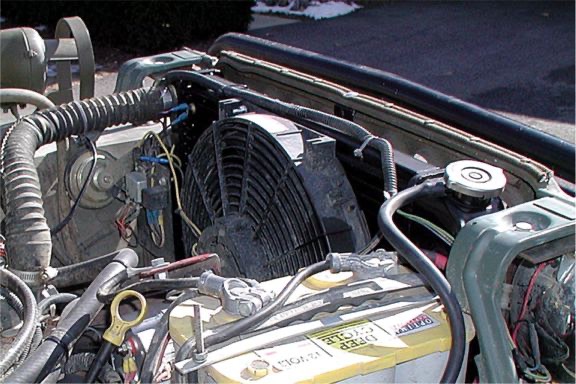

The old 1978 Chevy Monza developed several leeks in the main core and had a stress crack near the cap. I don't understand it, a mere 24 years old with not that much banging and hammering. It is quite a unique radiator. It is the usual 26 inches wide but is very short in depth. and fitted the MB grill perfectly. When I asked John Toumbs to do my winter check on the Willys and fit a new radiator you just know you are going to get more than you expect. John is beyond thorough. Yep, I had holes in the radiator, but John wanted to know why. He mounted the new radiator to reduce stress He mounted the cooling fan so no ties are pushed through the radiator that could cause a potential leak. He mounted the transmission and power steering coolers with new mounting brackets for the same reason. He then surmised the grill had been flexing a little more than he liked so he fabbed rubber isolated mounting brackets to prevent this. Enlarge the pictures below and take a look at his work.

The Willys had sagged over 3 inches since the Currie springs were installed. This is very disappointing considering that Currie is renown for top shelf products. These were YJ Wrangler springs. The Willys is way lighter than a YJ so I hate to imagine what they would look like on a YJ after just 2 years of wheeling!! As it turns out the springs were of fairly poor quality manufactured in Mexico. John installed add-a-leaves to bring it back up and eliminate the driver side sag. If you compare the photos above to the photos in the "Details" page you see that it has grown in height. I like the look but I think it will sag again.

John checked out everything else on the Jeep and found no surprises. The u-joints all looked sound with no signs of wear. The rest of the Willys looked like it was ready for another season of hard wheeling.